THE MAKING OF THE FLUTE

I learned to make flutes by watching Raymond Red feather?s ?Working with the Heart in the Wood? Native American Flute Making Video?. After a year and two hundred flutes, I have my own style. The way I do it is as follows: Obtain two 1? x 2? x 24-8? strips of wood (primarily, I use poplar, cherry, walnut, and hard maple cut to form at Lowes...$10 to $20 per flute) I mark the strips off 2? for the mouth hole, 5? for the slow air chamber, leave ? inch for blocking the slow air chamber from the true air chamber, and 14? from the estimated placement of the reed hole. The strips are routed, using a 7/8? core box router bit (1/2 hour). The chambers are sanded, and the strips are glued together using regular wood glue (1/2 hour). The flute is left 24 hours to dry. Then, the roost is routed to fit the spacer (the brass metal spacer plate... I obtain this from Leroy Cully, in Amy, Oklahoma at $2.00 each). The flute is routed to reduce the walls to 3/16? square (1/2 hour). If the flute has a carving, the pattern is traced and cut to shape using a scroll table saw. The mouth hole is drilled with a 3/16? drill bit. And the mouth piece is formed with a scroll saw. Using heated metal rods, the Slow Air Chamber is burned to exhaust the air from the SAC, and the True Air Chamber TAC is burned both holes are ?? square. The SAC is smoothed and the edge toward the mouth is sharpened at a 33? angle, and the TAC edge near the head of the flute must also be sharpened at a 33? angle, as well. The six playing holes are lined up, and marked off, the first hole being 3 11/16? from the reed, and the next five holes are located 1? apart . The ??four winds? holes are 14? from the reed (1/2 hour). At this point, the fetish must be made. This ?bird? sits on the roost, and blocks the air to redirect it to hit the reed. The fetish is formed by the use of a scroll saw, and shaped by filing and sanding. The chimney, eyes, mouth and ears are burned into place (one hour). A piece of rawhide holds the fetish into place. The flute is given a test at this time to see if it passes ?quality control?. If it plays F or G and makes the appropriate shifts and changes in certain notes, and does not hold onto a note too long. Etc. the process continues. The flute is rounded into shape using rasps and sandpaper. The carving is formed and the ears, eyes, and mouth are burned in (1 hour). The flute is brought to a smooth finish and dipped in ?boiled linseed oil?. The flue is tested using a chromatic tuner. My flutes are a low G or high F (1/2 hour). Anything else is unacceptable. I do not find it necessary to ?fine tune? the flute. When you tamper with the playing holes, you compromise the aesthetic quality of the flute, and gain very little. If you place the holes correctly, make them the right size, make the walls 3/16?, make the roost level, make the reed 3/16? at 33?, use a spacer... the flute makes an incredibly beautiful sound, and makes beautiful Indian Music...Teton Sioux Indian Music. |

MY TOOLS

| A ROUTER AND A FEW HAND TOOLS

LOTS OF WORK

FILES RASPS SANDPAPER

LOTS OF SAWDUST |

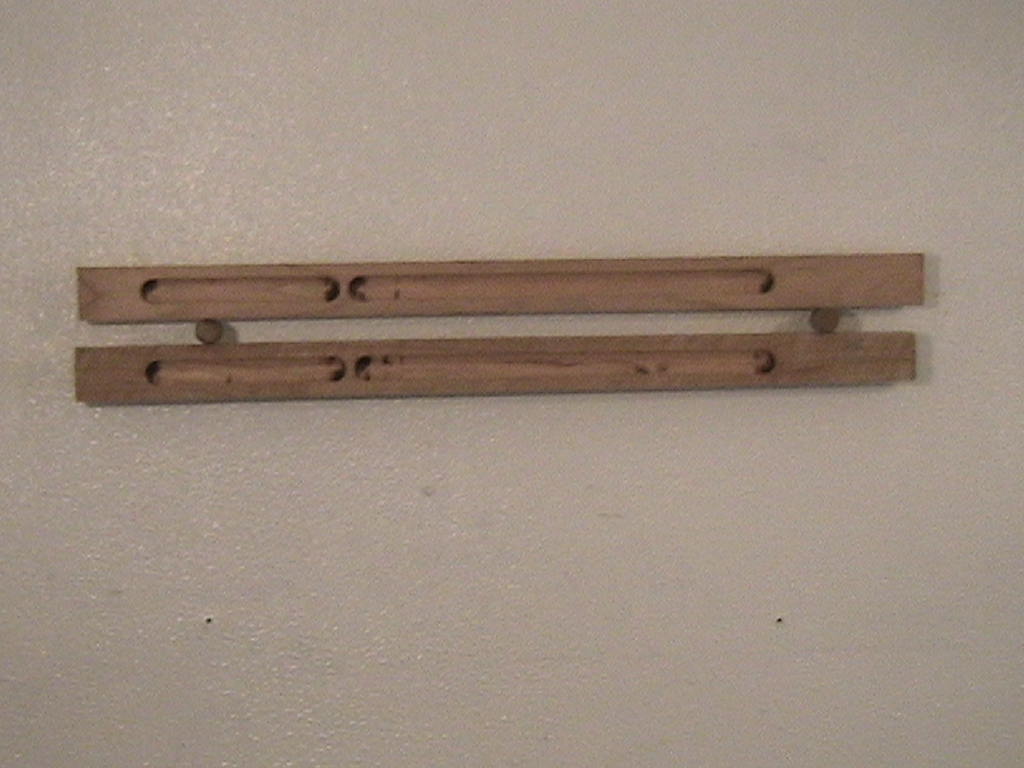

TWO STRIPS OF WOOD

| YOU BEGIN WITH TWO 1"x 2" x 30" STRIPS OF WOOD

plained on both sides

SMOOTH AND STRAIGHT

I had to plain the last ones...with a router...hard work. |

ROUTED

| Mark the strips and rout a 7/8" chamber in each magazine

using a core box router bit

sand the chambers

mirrow smoothe |

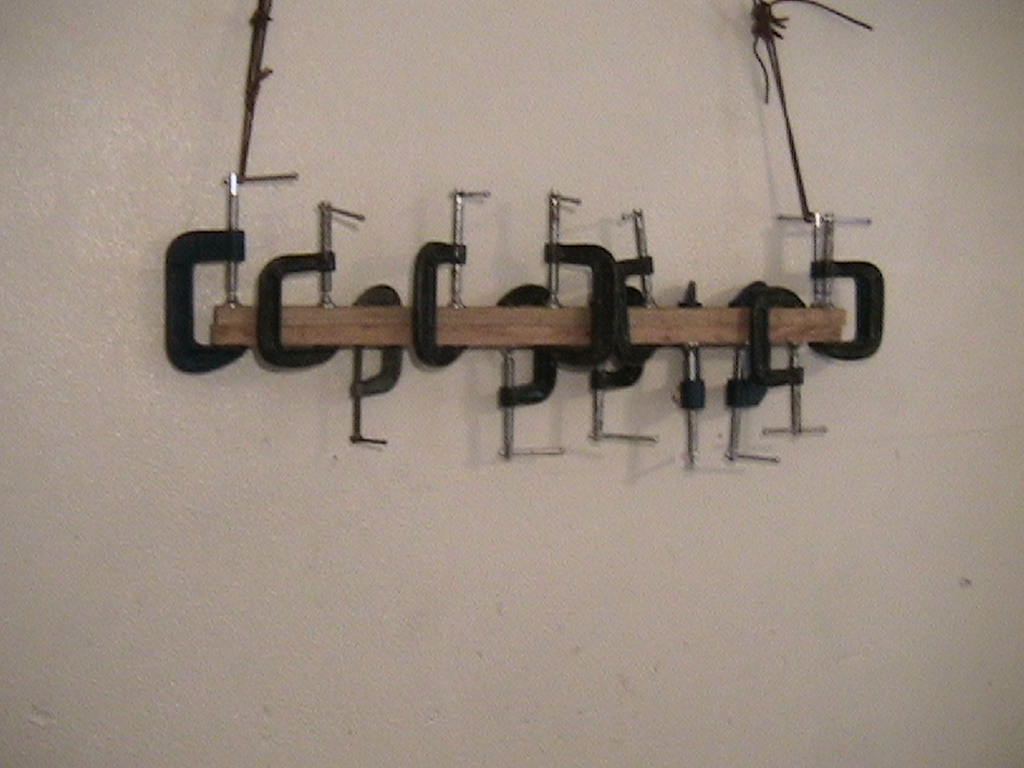

GLUED

| APPLY WOOD GLUE

AND CLAMP THE TWO STRIPS

STRAIGHT AND TIGHT

LET IT DRY FOR 24 HOURS |

WALNUT DUCK

CHERRY WOLF

DRAGON MADE OUT OF RED OAK

The flutes may be purchased at The Indian Village in Bastian, Virginia and at the Gift Shop in Pipestem, West Virginia

|

|